产品中心 RO membranes

4" Spiral Wound Elements for Sea Water

Introduction:

High Rejection, High Productivity:

4″ Spiral Wound Elements for Sea Water

Hydro-Flex reverse osmosis (RO) 4″ elements are some of the finest products in the industry. The state of the art coating line,

coupled with advanced membrane technology, yields product of the highest quality and most stable performance.Hydro-Flex

elements are uniquely engineered to have a high level of salt rejection with minimum compromise in water flux.

Description:

Membrane material: Polyamide thin film composite

Spirally wound element

Epoxy-based FRP overwrap

High pressure application for sea water treatment

Specifications:

| Product | Active area ft2 (m2) | Feed spacer thickness mil(mm) | Permeate flow rate gpd(m3/d) | Stabilized salt rejection (%) | Minimum | Test Conditions |

| FX-4021-SW | 33(3.1) | 28(0.7) | 800(3.0) | 99.4% | 99.0% | 800psi/32800ppm |

| FX-4040-SW | 80(7.4) | 28(0.7) | 1950(7.4) | 99.4% | 99.0% | 800psi/32800ppm |

1. All performance data are collected at 25°C (77°F), NaCl solution, pH7.5 and recovery rate FX-4040-SW 8%, FX-4021-SW 4%.

2. Permeate flows for single element may vary ± 20%.

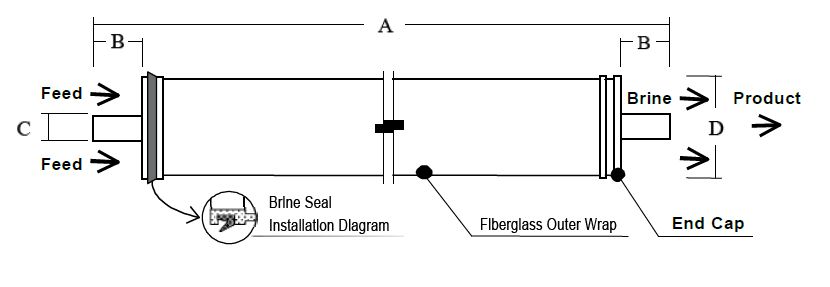

Element Dimension:

| Product | Recovery Rate % | Dimensions – Inches (mm) | |||

| A | B | C | D | ||

| FX-4021-SW | 4 | 40.0 (1016) | 1.05 (26.7) | 0.75 (19.1) | 3.9(99) |

| FX-4040-SW | 8 | 40.0 (1016) | 1.05 (26.7) | 0.75 (19.1) | 3.9(99) |

* 1 inch= 25.4 mm

Operating Limits for Design:

Maximum Operating Temperature………..…………….……...……45°C(113°F)

Maximum Operating Pressure………………..……………………...1000psi(69bar)

Maximum Pressure Drop (single element)……………………..……15psi(1.0bar)

pH Range for Continuous Operation……………………..................3-11

pH Range for Cleaning………………………………...………………1.5-12

Chlorine tolerance………………………………………………………<0.1ppm

Maximum Feed SDI…………………………………..........…….…….5

Important Operation Notes:

• It is critical to follow approved start-up procedure to prevent membrane damage due to overfeeding or hydraulic shock.

Before initiating system, loading of the RO elements, instrument calibration, membrane pretreatment and other system

checks should be conducted.

• Minimize any pressure shock or cross-flow fluctuation on the spiral elements at all times. During start-up, a gradual,

incremental change from a standstill to operating state is recommended.

• Maximum pressure drop across an entire pressure vessel (housing) is 50psi (3.4 bar).

• No static pressure should ever be built up on permeate side.

• Keep elements moist at all times after initial wetting.

• If operating limits and guidelines are not followed, the Limited Warranty will be void.

• In case of prolonged system shutdowns, it is recommended that membrane elements be immersed in a preservative

solution to prevent bacteria growth.

• Permeate collected from first hour of operation should be discarded.

• It is customer’s responsibility to make sure that the chemicals and lubricants do not have detrimental effects

on RO elements.